Over-familiarity with a task can catch out even the most experienced engineer.

On an otherwise routine Saturday morning earlier in 2025, long-time LAME Jay McIntyre received a worrying call.

It was from a client who had only just flown off. “Jay, I’m in a paddock near the coast. Had a prop overspeed. I pulled back on the throttle, but it only sped up.

“The engine quit and I ditched on a stop bank. We’re okay, but the plane’s a bit munted.”

Photo courtesy of JEM Aviation.

Jay – Director of Omaka-based JEM Aviation – admits he was confused while driving out to the site of the damaged Piper Arrow, as a prop overspeed would normally be caused by a lack of oil.

His company had only just completed the aircraft’s 100- hour annual. A new oil cooler, oil hoses, and quick drain valve had been fitted.

JEM Aviation had performed all the usual checks and tests before returning the aircraft to its owner. To ensure everything was working fine, Jay had asked the pilot to perform several circuits before they headed back to Auckland.

When Jay arrived at the stop bank, he saw signs of oil in the engine bay and on the belly of the Arrow.

“I checked the dipstick, and sure enough, there was no oil in the engine.

“But the cooler and hoses looked fine and the quick drain had been correctly lock-wired. I pushed the oil drain up and a little bit came out. That was very odd.

“Then I noticed some marks on the quick drain valve and I thought, ‘Those guys have used a pair of pliers to put it in!’

“Literally, five seconds later, it hit me. I thought, ‘Oh no… the undercarriage linkage has hit the quick drain and opened it during flight’.”

Jay went home that night and googled, ‘quick drain valve and Piper Arrow’.

“It popped up straight away. There had been an AD out since 1980 warning about installing non-compliant oil valves on the Piper Arrow.”

Over-familiarity

Photo courtesy of JEM Aviation.

Jay’s a very experienced engineer. His career began back in 1989 with the Royal New Zealand Air Force.

“I’ve worked on a lot of Piper aircraft over the years, and drained oil countless times – over-familiarity with the task probably led to complacency.

“When one of the guys asked if we should install a quick drain on the Arrow, I thought, ‘Yeah, that makes sense’.”

Quick drain valves allow an engineer to hook up a hose to the oil valve and route it away to a bucket.

“It’s much cleaner,” says Jay. “Otherwise, the oil can end up all over the airbox and so on. It can be quite a job to clean up.

“The original oil drain plug on this Arrow was a real swine to get to as well, so it seemed like a good idea at the time.”

Jay checked the compatibility of the quick drain valve against the engine make on the McFarlane website, and it checked out.

“But if I’d gone to the website of the company that makes the valve, I would have seen a warning about not fitting them to certain aircraft.

“Likewise, there was a generic warning in the aircraft maintenance manual, about using the correct drain valve.

“However, in the approved Piper check list for the inspection, the warning was not repeated. This was something you would think would be a no-brainer!”

Over-familiarity with a certain task, however, breeds a level of contempt, says Jay.

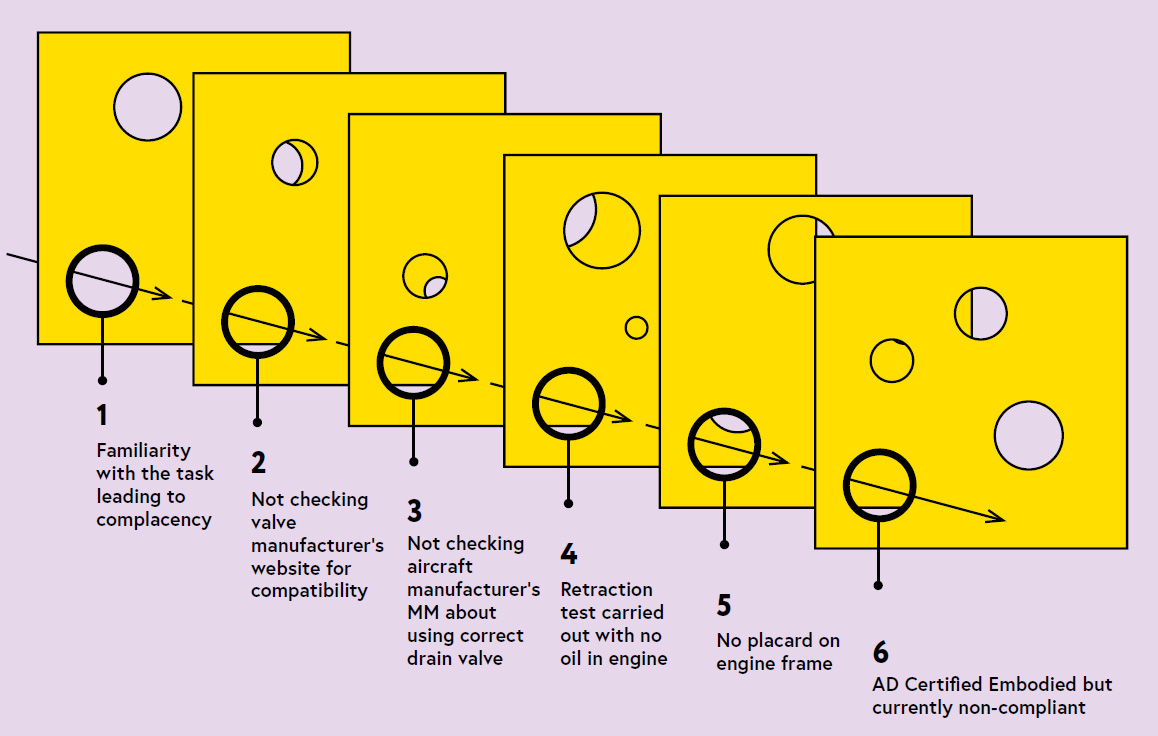

Illustration: Gusto

Swiss cheese

Several other factors led to the prop overspeed.

“It was very, very definitely a Swiss cheese situation,” says Jay.

To start with, Jem Aviation completed the inspection including landing gear retracting tests, without any oil in the engine.

“We were waiting for the replacement oil cooler to arrive from offshore,” says Jay. “That took about a month, and we completed as much of the inspection as we could in the meantime.

“That was never going to show us the problem.

“It wasn’t until the pilot retracted his landing gear as he performed those circuits that the Arrow began to lose oil.”

A couple of minutes after the pilot set course for Auckland, all the oil was all gone.

“It was all over by then,” says Jay.

Another hole in the cheese was the absence of the warning placard on the engine mount frame that formed part of the AD.

“The AD requiring the placard was signed off in 1981 as being embodied. I’m guessing it was never refitted when the engine was overhauled, the engine mount non-destructive tested, and repainted in 2008 – if not before,” says Jay.

“If the warning placard had still been there, we never would have fitted the quick drain.”

After the incident, Jay checked another Arrow at his local aerodrome.

“That was missing its oil drain warning placard as well. And I know of another Arrow in Auckland that doesn’t have one any more.”

“It’s a tough one.

“On reviewing the ADs when we took over the maintenance of the aircraft in 2024, I looked through the AD listings and saw that everything was signed off as having been embodied.

“ADs that were listed as ‘Repetitive’ by the CAA were recorded appropriately, but this particular AD is not classed as a Repetitive AD.”

Jay wonders if perhaps this AD should be repetitive.

“Maybe when a new type comes into the shop, I need to fully review all the ADs so these little traps can’t catch us out again.

“Having said that, it doesn’t absolve me from not having followed the procedure in the maintenance manual.

“Ultimately, the responsibility rests with me.”

Vector is very grateful to Jay for his story. It takes courage and professional maturity to publicly share what went wrong, so other LAMEs can learn from his story.

CAA actions

The CAA has reviewed the AD schedule for the Piper Arrow following this event, says Principal Advisor of Airworthiness, Warren Hadfield.

“The CAA cancelled DCA/PA28/174 and issued FAA AD81-11-02 R1 on 25 September 2025.

“The AD in question does not mandate a repetitive inspection. However, it is critical to understand the associated placard is not a fit and forget item.

“It’s the operator’s responsibility to ensure that the aircraft complies with all applicable AD requirements.

“This includes ensuring that mandatory placards are fitted and legible.

“The CAA has contacted the affected operators to remind them of the AD. We have also released CAN 05-017 which explains AD compliance requirements.”

FAA AD81-11-02 R1 [PDF 412 KB]

CAN 05-017 - Airworthiness Directive Compliance [PDF 166 KB]

Footnote

Skybrary: Swiss cheese model of accident causation(external link)